When it comes to precision engineering, construction, and manufacturing, Round Bars and Rods are some of the most versatile and widely used products in the steel industry. At Max Steel & Engineering Co., we take pride in being one of the leading manufacturers, exporters, and suppliers of premium-quality round bars and rods that meet global standards.

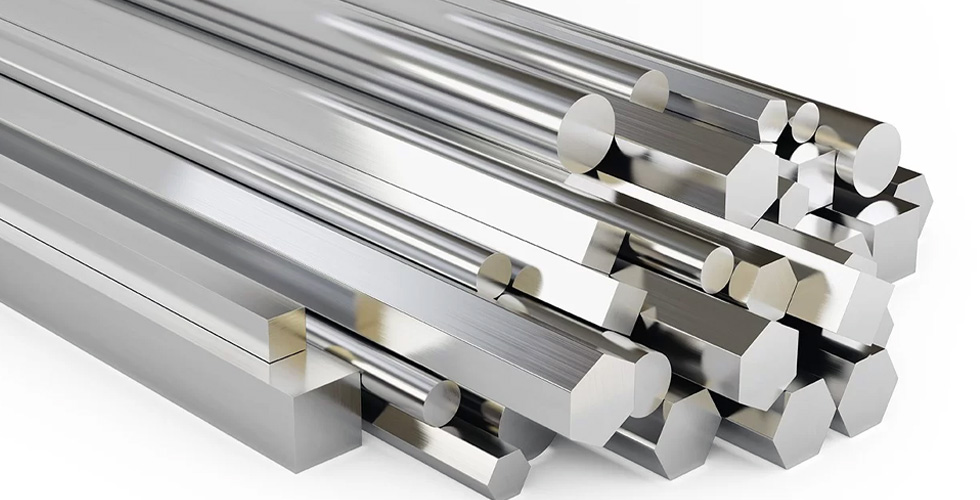

Round bars and rods are long, cylindrical metal products with a wide range of applications. They are manufactured in different grades of stainless steel, carbon steel, alloy steel, duplex steel, nickel alloys, and more to cater to diverse industries.

With our steel round bars, we were able to attain superior weldability, high tensile strength, longer tool life, improved surface polish, and ease of installation. These round bars, wires, and rods are widely used in the automobile, shipbuilding, petroleum, bright bars, welding electrode, household applications, and agricultural sectors, among others.

Duplex and Super Duplex Steel, Stainless Steel, Hastelloy, Monel, Inconel, Nickel, Cupronickel, and many other material grades are among the numerous that we use in the production of these round bars, rods, and wires. Additionally, we provide them in various forms, such as forged bars and rods, cold-rolled round bars and rods, and hot-rolled round bars and rods. For a free estimate, please get in touch with us right now.

| Dimension | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Range | 100 MM To 3000 MM Long & Above |

| Size | 5 MM To 500 MM |

| Round Bars | Outside Diameter in the range of 4mm to 500mm |

| Bright Bars | Outside Diameter in the range of 4mm to 100mm |

| Hex Bars | 18mm – 57mm (11/16? to 2-3/4?) |

| Square Bars | 18mm – 47mm (11/16? to 1-3/4?) |

| Flat Bars | 1/2” to 10” in thickness range of 2mm to 150mm |

| Wire Size | 0.1 mm to 10 mm |

| Form | Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc. |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sandblast, Brush, etching, etc |

| Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

Round Bars

Square Bars

Hexagonal Bars

Threaded Rods

Hollow Bars

Steel Billets

Forged Bars

Wires

| Round bar Cutting | Products cut include Round bars, Flat bars, Hex bars, Square bars, Tubing and Hollow bars, Pipe, Angles, channels, Beams and Tees. Thickness range is 1/16″ to 28″ diameter |

|---|---|

| Round bar Production Cutting | We can provide production cutting for product diameters up to 4″. We utilize Amanda Production Equipment to achieve these precision cuts with tight tolerances. |

| Round bar Polishing | Products polished included all tubular products, with OD & ID polishing available, Round bars, Square bars, Hex & Flat bars, Angles, Uneven Leg Angles, beams, and other shapes. |

| Standards | ASTM A276 / A182 / A479 |

| Grades | 201, 202, 301, 302, 304, 304L, 309, 310, 316, 316L, 316LN, 317L, 321, 330, 347, 405, 409, 410, 416, 420, 430, 431, 440C, 17-4ph, 904L, AL-6XN (N08367), Nitronic 50 / 60, 422, 416, 446, Nimonic 80 (N07080), A286 (S66286), 15-5ph, Alloy 28 (N08028). |

| Standards | ASTM A234 / A420 / A860 |

| Grades | Gr. WPB, Gr. WPL-3, WPL-6, IS 1239, IS 3589, WPHY42, WPHY46, WPHY52, WPHY60, WPHY65, WPHY70 |

| Standards | ASTM A182, ASME SA182 |

| Grades | F1, F5, F9, F11, F12, F22, F91, 4140, 4130, Kanthal A1, Nichrome 80/20. |

| Standards | ASTM A182 |

| Grades | 2205 (F51, S31803 / F60, S32205), SMO254 (F44, S32154), 2507 (F53, S32750 / F55, S32760), Ferralium 255 (F61, S32550), SMO 654 (S32654), 329 (S32900). |

| Standards | ASTM B160 / B473 |

| Grades | 200 (N02200), 201 (N02201), Alloy 20 (N08020). |

| Standards | ASTM B164 / ASME SB164 |

| Grades | 400 (N04400), 500 (N05500). |

| Standards | ASTM B166 / B408 / B425 |

| Grades | 600 (N06600), 601 (N06601), 625 (N06625), 718 (N07718), 800 (N08800), 800H (N08810), 800HT (N08811), 825 (N08825), 925 (N08925), 926 (N08926). |

| Standards | ASTM B574 / B572 / B335 |

| Grades | C726 (N10276), C4 (N06455), C22 (N06022), C2000 (N06200), X (N06002), B2 (N10665), B3 (N10675). |

| Standards | ASTM / ASME SB 62 |

| Grades | UNS C12200 |

| Standards | ASTM B348/ ASME SB348 |

| Grades | 2, 5 (Ti6AI4V), 7. |

| Standards | ASTM / ASME SB 62 |

| Grades | UNS C36000 |

| Standards | ASTM B187, ASTM B301 / ASME SB187, SB301 |

| Grades | ASTM B134 |

| US Bar | Metric | Japanese | Canadian/ASTM | ||||

|---|---|---|---|---|---|---|---|

| Diameter(Inch) | Bar Size | Diameter (millimeter) | Bar Size | Diameter (millimeter) | Bar Size | Diameter (millimeter2) | Bar Size |

| 0.250 | #2 | 5 | 5 | 6 | 6 | 100 | 10M |

| 0.375 | #3 | 5.5 | 5.5 | 10 | 10 | 200 | 15M |

| 0.500 | #4 | 6 | 6 | 13 | 13 | 300 | 20M |

| 0.625 | #5 | 7 | 7 | 16 | 16 | 500 | 25M |

| 0.750 | #6 | 8 | 8 | 19 | 19 | 700 | 30M |

| 0.875 | #7 | 9 | 9 | 22 | 22 | 1000 | 35M |

| 1.000 | #8 | 10 | 10 | 25 | 25 | 1500 | 45M |

| 1.125 | #9 | 11 | 11 | 29 | 29 | 2500 | 55M |

| 1.250 | #10 | 12 | 12 | 32 | 32 | ||

| 1.375 | #11 | 14 | 14 | 35 | 35 | ||

| 1.500 | #12 | 16 | 16 | 38 | 38 | ||

| 1.625 | #13 | 18 | 18 | 41 | 41 | ||

| 1.750 | #14 | 20 | 20 | 44 | 44 | ||

| 1.875 | #15 | 22 | 22 | 48 | 48 | ||

| 2.000 | #16 | 25 | 25 | 51 | 51 | ||

| 2.250 | #18 | 28 | 28 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

| 50 | 50 | ||||||

| Bar Size | kilogram / Meter | kilogram / Foot | Size | kilogram / Meter | kilogram / Foot | Size | kilogram / Meter | kilogram / Foot |

|---|---|---|---|---|---|---|---|---|

| 1/8" | 0.062 | 0.019 | 22 millimeter | 2.979 | 0.908 | 3 to 1/4" | 41.996 | 12.800 |

| 3 millimeter | 0.055 | 0.017 | 20 millimeter | 2.470 | 0.753 | 3" | 35.762 | 10.900 |

| 4 millimeter | 0.098 | 0.030 | 24 millimeter | 3.543 | 1.080 | 3 to 3/4" | 55.780 | 17.001 |

| 5/32" | 0.095 | 0.029 | 7/8" | 3.038 | 0.926 | 3 to 1/2" | 48.772 | 14.850 |

| 5 millimeter | 0.154 | 0.047 | 1" | 3.970 | 1.210 | 4 to 1/4" | 72.249 | 21.908 |

| 3/16" | 0.141 | 0.043 | 25 millimeter | 3.871 | 1.180 | 4" | 63.340 | 19.306 |

| 6 millimeter | 0.223 | 0.068 | 27 millimeter | 4.490 | 1.368 | 4 to 3/4" | 90.249 | 27.366 |

| 7/32" | 0.190 | 0.058 | 26 millimeter | 4.170 | 1.271 | 4 to 1/2" | 80.340 | 24.4487 |

| 7 millimeter | 0.298 | 0.091 | 30 millimeter | 5.548 | 1.691 | 5 to 1/2" | 121.000 | 36.690 |

| 1/4" | 0.249 | 0.076 | 1 to 1/8" | 5.033 | 1.534 | 5" | 99.940 | 30.461 |

| 8 millimeter | 0.398 | 0.120 | 32 millimeter | 6.314 | 1.894 | 6 to 1/2" | 167.630 | 51.093 |

| 5/16" | 0.387 | 0.118 | 1 to 1/4" | 6.349 | 1.924 | 6" | 143.900 | 43.860 |

| 3/8" | 0.557 | 0.170 | 35 millimeter | 7.553 | 2.390 | 7 to 1/2" | 225.000 | 68.226 |

| 9 millimeter | 0.498 | 0.152 | 1 to 3/8" | 7.550 | 2.303 | 7" | 196.000 | 59.432 |

| 11 millimeter | 0.748 | 0.228 | 38 millimeter | 8.903 | 2.792 | 10" | 397.140 | 121.048 |

| 10 millimeter | 0.620 | 0.189 | 36 millimeter | 7.999 | 2.438 | 8" | 254.55 | 77.586 |

| 12 millimeter | 0.889 | 0.271 | 40 millimeter | 9.872 | 3.009 | |||

| 7/16" | 0.761 | 0.232 | 1 to 1/2" | 8.951 | 2.715 | |||

| 13 millimeter | 1.043 | 0.318 | 1 to 3/4" | 12.179 | 3.712 | |||

| 1/2" | 0.994 | 0.303 | 1 to 5/8" | 10.449 | 3.200 | |||

| 9/16" | 1.256 | 0.383 | 1 to 7/8" | 13.977 | 4.260 | |||

| 14 millimeter | 1.207 | 0.368 | 45 millimeter | 12.555 | 3.807 | |||

| 5/8" | 1.551 | 0.473 | 50 millimeter | 15.414 | 4.698 | |||

| 15 millimeter | 1.391 | 0.424 | 48 millimeter | 14.205 | 4.330 | |||

| 17 millimeter | 1.791 | 0.543 | 2 to 1/8" | 17.963 | 5.475 | |||

| 16 millimeter | 1.578 | 0.481 | 2" | 15.906 | 4.848 | |||

| 18 millimeter | 2.001 | 0.610 | 60 millimeter | 22.205 | 6.768 | |||

| 11/16" | 1.880 | 0.573 | 2 to 1/4" | 20.128 | 6.135 | |||

| 3/4" | 2.237 | 0.682 | 2 to 3/8" | 22.435 | 6.838 | |||

| 2 to 1/2" | 24.856 | 7.576 | ||||||

| 2 to 5/8" | 27.409 | 8.354 | ||||||

| 2 to 3/4" | 30.083 | 9.169 |

| Turned Round Bar Tolerances | |

|---|---|

| Round Bar Size, Diameter | Permitted variation |

| milimeter | milimeter |

> 18 ≦ 30 ≧ 6 ≦ 18 > 400 > 50 ≦ 80 > 30 ≦ 50 > 120 ≦ 180 > 80 ≦ 120 > 250 ≦ 315 > 180 ≦ 250 > 315 ≦ 400 |

+ 0 to - 0.085 + 0 to - 0.070 + 0 to - 0.230 + 0 to - 0.120 + 0 to - 0.140 + 0 to - 0.185 + 0 to - 0.160 + 0 to - 0.210 + 0 to - 0.250 |

| Bars Section/Shape | diameter, width or Size across flats | variation Permitted |

|---|---|---|

| millimeter | millimeter | |

| Flat (Thickness) | < 18 > 30 ≦ 50 > 18 ≦ 30 > 50 ≦ 80 |

+ 0 to - 00.110 + 0 to - 00.250 + 0 to - 00.130 + 0 to - 00.350 |

| Square and Hexagon | > 18 ≦ 30 ≥ 6 ≦ 18 > 30 ≦ 50 > 80 ≦ 105 > 50 ≦ 80 |

+ 0 to - 00.110 + 0 to - 00.090 + 0 to - 00.130 + 0 to - 00.250 + 0 to - 00.160 |

| Round | > 18 ≦ 30 ≥6 ≦ 18 > 30 ≦ 50 > 80 ≦ 100 > 50 ≦ 80 |

+ 0 to - 00.085 + 0 to - 00.070 + 0 to - 00.100 + 0 to - 00.140 + 0 to - 00.120 |

| Flat (Width) | < 18 > 30 ≦ 50 > 18 ≦ 30 > 50 ≦ 80 > 160 ≦ 320 > 100 ≦ 130 > 80 ≦ 100 > 130 ≦ 160 |

+ 0 to - 00.110 + 0 to - 00.160 + 0 to - 00.130 + 0 to - 00.190 + 1.00 to - 1.00 + 0 to - 00.350 + 0 to - 00.220 + 0 to - 1.00 |

Max Steel & Engineering Co. manufactures and exports Round Bar to various countries such as Saudi Arabia, Bangladesh, United States, United Arab Emirates, Canada, Angola, Argentina, Austria, Azerbaijan, Pakistan, Peru, Chile, Kuwait, Mexico, Malaysia, Nigeria, Serbia, Singapore, Taiwan, Chile, Venezuela, Ecuador, Netherlands, Brazil, Vietnam, South Africa, Nigeria, Mexico, Turkey, Hungary, Algeria, Belarus, Belgium, Bhutan, Bolivia, Bulgaria, Croatia, Czech Republic, Estonia, Finland, Greece, Italy, Japan, Libya, Colombia, Ghana, Iran, Denmark, Poland, Australia, Afghanistan, Bahrain, Costa Rica, Egypt, Iraq, Jordan, South Korea, Kazakhstan, Sri Lanka, Lithuania, Norway, Oman, Philippines, Poland, Qatar, Spain, France, United Kingdom, Indonesia, Israel, Iran, Russia, Romania, Thailand, Trinidad & Tobago,Tunisia, Ukraine, Yemen, Hong Kong, Gabon, China, Portugal, Switzerland, New Zealand, Sweden, Slovakia, Kenya, Lebanon, Morocco, Mongolia

Max Steel & Engineering Co. manufactures and exports Round Bar to multiple cities such as Mumbai, Thane, Navi Mumbai, Pune, Pimpri-Chinchwad, Vadodara, Kolkata, Gurgaon, Ahmedabad, Seoul, Hyderabad, Singapore, Abu Dhabi, Tehran, Calgary, Noida, Riyadh, London, Coimbatore, Jakarta, Istanbul, Bangkok, Kuwait City, Sharjah, Muscat, Edmonton, Busan, Mexico City, Doha, New Delhi, Bengaluru, Chennai, Surat, Bhopal, Ulsan, Faridabad, Houston, Dubai, Jeddah, Aberdeen, Cairo, Geoje-si, Perth, Santiago, Chandigarh, Indore, Kuala Lumpur, Rio de Janeiro, Dammam, Melbourne, Madrid, La Victoria, Bogota, Lahore, Los Angeles, Algiers, Chiyoda, Ankara, Ho Chi Minh City, Toronto, Hong Kong, Howrah, Sydney, Ahvaz, Karachi, Rajkot, Brisbane, Petaling Jaya, Ernakulam, Secunderabad, Gimhae-si, Al Jubail, Port-of-Spain, Thiruvananthapuram, Milan, Atyrau, Lagos, Hanoi, New York, Caracas, Vung Tau, Al Khobar, Manama, Montreal, Granada, Courbevoie, Visakhapatnam, Ludhiana, Moscow, Dallas, Haryana, Colombo.

Our Mission

Our mission is to be a premier provider of stainless steel solutions, offering products that meet the highest industry standards and exceed the expectations of our customers. We strive to contribute to the success of our clients by providing them with durable, innovative, and sustainable stainless steel products.

Max Steel & Engineering Co. provides Round Bar at reasonable prices in the market. You can Contact us to get the updated price list of Round Bar. Our prices are best for all types of Round Bar.