At Max Steel & Engineering Co., we take pride in being recognized as a trustworthy name in the global market. With years of expertise and a commitment to excellence, we specialize in manufacturing, exporting, and supplying a comprehensive range of Sheets, Plates, and Coils.

Driven by innovation and precision, our products are crafted to meet international quality standards and cater to diverse industries worldwide. Whether it’s durability, performance, or reliability, we ensure that every product we deliver reflects our core values of quality, integrity, and customer satisfaction.

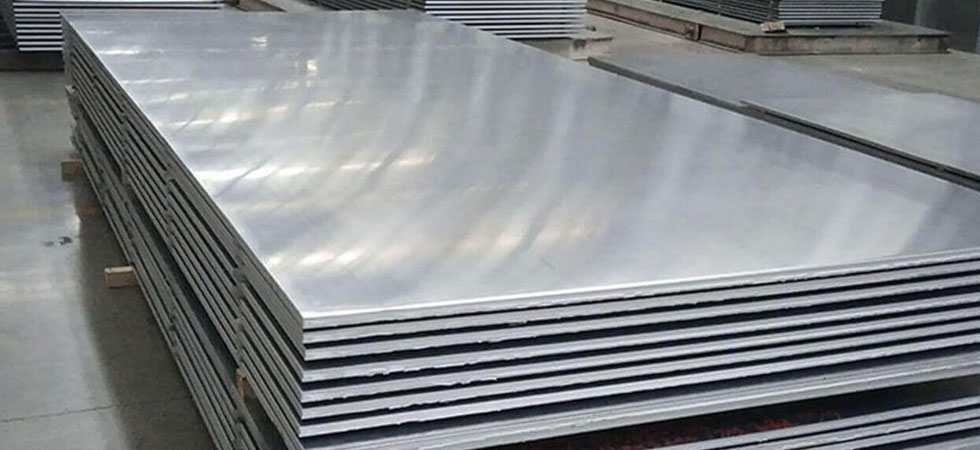

The sheet is a metal component with a thickness of under three millimeters. Conversely, Plate has a thickness more than 3mm. This is how to differentiate between plates and sheets the best. Moreover, coils are collections of circularly organized metal wires. We use a variety of material grades, including Stainless Steel, Nickel Alloy, Inconel, Monel, Hastelloy, Super Duplex and Duplex Steel, and many more, to create these Sheets, Plates, and Coils.

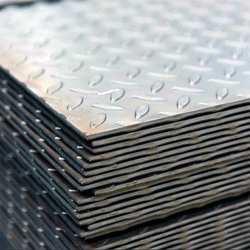

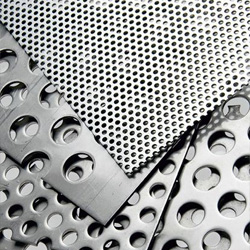

Additionally, sheets and plates come in a range of forms, including hot-rolled, cold-rolled, decorative, shim, perforated, and galvanized sheets and plates, among others. Many industries, including as shipbuilding, construction, building materials, heat exchanger manufacture, maritime applications, and more, have a high demand for our premium sheets, plates, and coils.

| Thickness | 4mm-100mm |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, Mirror, Checkered, Embossed, Hairline, Sand Blast, Brush, Etching, etc |

| Finish | Hot Rolled Plate (HR), Cold Rolled Sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

Shim Sheets

Coils

Cold Rolled Sheets

Chequered Plates

Perforated Sheets

Flat

Circle (Blanks)

Foils

Strips

Rings

Profiles

B. Q. Profile

| Surface Finish | Definition | Application |

|---|---|---|

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe |

| Standards | ASTM A240 / ASME SA240 |

| Grades | 201, 202, 301, 302, 304, 304L, 309, 310, 316, 316L, 316LN, 316Ti, 317L, 321, 347, 405, 409, 410, 420, 430, 440C, 17-4ph, 904L, 253MA, 353MA, AL-6XN (N08367), Alloy 28 (N08028), A286 (S66286). |

| Standards | ASTM A36 |

| Grades | S275JR,IS-2062 GR. A / B, Fe 410WA, Fe 410WB |

| Standards | ASTM A240 / ASME SA240, ASTM A479 / ASME SA479 |

| Grades | 2205 (S31803 / S32205), SMO254 (S31254), 2507 (S32750), ZERON 100 (S32760), Ferralium 255 (S32550), LDX 2101 (S32101). |

| Standards | ASTM A36, IS 2062, CK60, Wear Resistant Steel, Boiler Quality ASTM A516 |

| Grades | 400 HB, 450 HB, 500 HB, 60, 70, Corten A, Corten B, Hadfield Manganese Steel |

| Standards | ASTM A387 / ASME SA387 |

| Grades | 11, 12, 22, 5, 9, 91, A283 Gr. C, 16Mo3 |

| Standards | ASTM / ASME SB122 |

| Grades | Cu-Ni 90 / 10 , Cu-Ni 70 / 30 |

| Standards | ASTM B162 / ASME SB162 |

| Grades | 200 (N02200), 201 (N02201), ASTM B463 – Alloy 20 (N08020). |

| Standards | ASTM B 168 / ASTM B 670 / ASTM B 443 |

| Grades | N06600, N06601, N06617 / N07718 / N06625 |

| Standards | ASTM B 575 / ASTM B 333 |

| Grades | N10276, N06022 / N10665 |

| Standards | ASTM / ASME SB 127 |

| Grades | Monel 400, Monel K500 |

| Standards | ASTM B575 / ASME SB575, ASTM B333 / ASME SB333 |

| Grades | C726 (N10276), C4 (N06455), C22 (N06022), C2000 (N06200), X (N06002), B2 (N10665), B3 (N10675). |

| Standards | ASTM / ASME SB 62 |

| Grades | UNS C36000 |

| Standards | ASTM / ASME SB 62 |

| Grades | UNS C12200 |

| Standards | ASTM / ASME SB209 |

| Grades | 6061, 6082, 5083, 5086, 5052 ,6063, 7075, 1100 |

| Standards | ASTM B256 / ASME SB256 |

| Grades | 2, 5 (Ti6AI4V), 7. |

| Thickness | Thickness | Size Range | Surface Area per Unit weight | Approx Weight per Sheet | ||

|---|---|---|---|---|---|---|

| inches | mm | lbs/ft² | kg/m² | lbs | kg | |

| 0.015 | 0.381 | 36 x 96 | 0.630 | 3.07566 | 15.12 | 6.84936 |

| 0.015 | 0.381 | 36 x 120 | 0.630 | 3.07566 | 18.90 | 8.5617 |

| 0.0178 | 0.45212 | 36 x 96 | 0.756 | 3.690792 | 18.15 | 8.22195 |

| 0.0178 | 0.45212 | 36 x 120 | 0.756 | 3.690792 | 22.68 | 10.27404 |

| 0.0178 | 0.45212 | 48 x 96 | 0.756 | 3.690792 | 24.19 | 10.95807 |

| 0.0178 | 0.45212 | 48 x 120 | 0.756 | 3.690792 | 30.24 | 13.69872 |

| 0.0235 | 0.5969 | 30 x 96 | 1.008 | 4.921056 | 20.16 | 9.13248 |

| 0.0235 | 0.5969 | 30 x 120 | 1.008 | 4.921056 | 25.20 | 11.4156 |

| 0.0235 | 0.5969 | 36 x 96 | 1.008 | 4.921056 | 24.19 | 10.95807 |

| 0.0235 | 0.5969 | 36 x 120 | 1.008 | 4.921056 | 30.24 | 13.69872 |

| 0.0235 | 0.5969 | 36 x 144 | 1.008 | 4.921056 | 36.29 | 16.43937 |

| 0.0235 | 0.5969 | 48 x 96 | 1.008 | 4.921056 | 32.26 | 14.61378 |

| 0.0235 | 0.5969 | 48 x 120 | 1.008 | 4.921056 | 40.32 | 18.26496 |

| 0.0235 | 0.5969 | 48 x 144 | 1.008 | 4.921056 | 48.39 | 21.92067 |

| 0.0291 | 0.73914 | 30 x 96 | 1.260 | 6.15132 | 25.20 | 11.4156 |

| 0.0291 | 0.73914 | 30 x 120 | 1.260 | 6.15132 | 31.50 | 14.2695 |

| 0.0291 | 0.73914 | 36 x 96 | 1.260 | 6.15132 | 30.24 | 13.69872 |

| 0.0291 | 0.73914 | 36 x 120 | 1.260 | 6.15132 | 37.80 | 17.1234 |

| 0.0291 | 0.73914 | 36 x 144 | 1.260 | 6.15132 | 45.37 | 20.55261 |

| 0.0291 | 0.73914 | 48 x 96 | 1.260 | 6.15132 | 40.32 | 18.26496 |

| 0.0291 | 0.73914 | 48 x 120 | 1.260 | 6.15132 | 50.41 | 22.83573 |

| 0.0291 | 0.73914 | 48 x 144 | 1.260 | 6.15132 | 60.49 | 27.40197 |

| 0.0355 | 0.9017 | 30 x 96 | 1.512 | 7.381584 | 30.24 | 13.69872 |

| 0.0355 | 0.9017 | 30 x 120 | 1.512 | 7.381584 | 37.80 | 17.1234 |

| 0.0355 | 0.9017 | 36 x 96 | 1.512 | 7.381584 | 36.29 | 16.43937 |

| Size (mm) | Weight per Sheet (Kg) | Size (mm) | Weight per Sheet (Kg) |

|---|---|---|---|

| 2000 x1000 x 0.7 | 11.5 | 2500 x 1250 x 1.5 | 38.4 |

| 2500 x1250 x 0.7 | 17.9 | 3000 x 1500 x 1.5 | 55.3 |

| 2000 x1000 x 0.9 | 14.7 | 2000 x 1000 x 2.0 | 32.7 |

| 2500 x1250 x 0.9 | 23.0 | 2500 x 1250 x 2.0 | 51.2 |

| 2000 x1000 x 1.0 | 16.4 | 3000 x 1500 x 2.0 | 73.7 |

| 2500 x1250 x 1.0 | 25.6 | 2000 x 1000 x 2.5 | 40.9 |

| 3000 x1500 x 1.0 | 36.8 | 2500 x 1250 x 2.5 | 63.9 |

| 2000 x1000 x 1.2 | 19.6 | 3000 x 1500 x 2.5 | 92.1 |

| 2500 x1250 x 1.2 | 30.7 | 2000 x 1000 x 3.0 | 49.6 |

| 3000 x1500 x 1.2 | 44.2 | 2500 x 1250 x 3.0 | 77.5 |

| 2000 x1000 x 1.5 | 24.6 | 3000 x 1500 x 3.0 | 112.0 |

Max Steel & Engineering Co. manufactures and exports Sheets, Plates & Coil to various countries such as Saudi Arabia, Bangladesh, United States, United Arab Emirates, Canada, Angola, Argentina, Austria, Azerbaijan, Pakistan, Peru, Chile, Kuwait, Mexico, Malaysia, Nigeria, Serbia, Singapore, Taiwan, Chile, Venezuela, Ecuador, Netherlands, Brazil, Vietnam, South Africa, Nigeria, Mexico, Turkey, Hungary, Algeria, Belarus, Belgium, Bhutan, Bolivia, Bulgaria, Croatia, Czech Republic, Estonia, Finland, Greece, Italy, Japan, Libya, Colombia, Ghana, Iran, Denmark, Poland, Australia, Afghanistan, Bahrain, Costa Rica, Egypt, Iraq, Jordan, South Korea, Kazakhstan, Sri Lanka, Lithuania, Norway, Oman, Philippines, Poland, Qatar, Spain, France, United Kingdom, Indonesia, Israel, Iran, Russia, Romania, Thailand, Trinidad & Tobago,Tunisia, Ukraine, Yemen, Hong Kong, Gabon, China, Portugal, Switzerland, New Zealand, Sweden, Slovakia, Kenya, Lebanon, Morocco, Mongolia

Max Steel & Engineering Co. manufactures and exports Sheets, Plates & Coil to multiple cities such as Mumbai, Thane, Navi Mumbai, Pune, Pimpri-Chinchwad, Vadodara, Kolkata, Gurgaon, Ahmedabad, Seoul, Hyderabad, Singapore, Abu Dhabi, Tehran, Calgary, Noida, Riyadh, London, Coimbatore, Jakarta, Istanbul, Bangkok, Kuwait City, Sharjah, Muscat, Edmonton, Busan, Mexico City, Doha, New Delhi, Bengaluru, Chennai, Surat, Bhopal, Ulsan, Faridabad, Houston, Dubai, Jeddah, Aberdeen, Cairo, Geoje-si, Perth, Santiago, Chandigarh, Indore, Kuala Lumpur, Rio de Janeiro, Dammam, Melbourne, Madrid, La Victoria, Bogota, Lahore, Los Angeles, Algiers, Chiyoda, Ankara, Ho Chi Minh City, Toronto, Hong Kong, Howrah, Sydney, Ahvaz, Karachi, Rajkot, Brisbane, Petaling Jaya, Ernakulam, Secunderabad, Gimhae-si, Al Jubail, Port-of-Spain, Thiruvananthapuram, Milan, Atyrau, Lagos, Hanoi, New York, Caracas, Vung Tau, Al Khobar, Manama, Montreal, Granada, Courbevoie, Visakhapatnam, Ludhiana, Moscow, Dallas, Haryana, Colombo.

Our Mission

Our mission is to be a premier provider of stainless steel solutions, offering products that meet the highest industry standards and exceed the expectations of our customers. We strive to contribute to the success of our clients by providing them with durable, innovative, and sustainable stainless steel products.

Max Steel & Engineering Co. provides Sheets, Plates & Coils at reasonable prices in the market. You can Contact us to get the updated price list of Sheets, Plates & Coils. Our prices are best for all types of Sheets, Plates & Coils.