In the world of industrial machinery and piping systems, valves play a crucial role in controlling the flow of liquids and gases. At Max Steel & Engineering Co., we specialize in manufacturing, exporting, and supplying high-quality valves designed to meet the rigorous demands of modern industries.

With decades of experience, Max Steel & Engineering Co. has established a reputation for excellence in the valve industry. We offer a comprehensive range of valves, including: Gate Valves, Globe Valves, Check Valves, Ball Valves, Butterfly Valves.

Our valves had wide spectrum of users in the Process and Chemical, Refineries & Petrochemicals, Fertilizers, Drugs and Pharmaceuticals, Thermal Power Stations, Nuclear and Atomic Power Stations, Textiles, Dyes and Intermediates, Paints & Varnishes, Sugar, Breweries and Distilleries, Soaps and Detergents, Steel Plants, Food and Oil industry, Solvent Extraction Plants, Sewage, Effluent & Water Treatment, Cooling Water, Ship Yards and Marine Management, Water works, Pulp & Paper, LPG Bottling Plants, Onshore & Offshore Platforms, Slurry and Ash handling

Valves are more than just mechanical components—they are the backbone of any fluid-handling system. Whether it’s controlling pressure, regulating flow, or ensuring safety, the right valve can significantly enhance operational efficiency and longevity. Choosing a reliable manufacturer ensures your systems run smoothly with minimal maintenance.

| Standard | API 600/BS1414, API 598/BS EN 12266-1, ASME B 16.10, ASME B 16.5, ASME B 16.25, ASME B 16.34 |

| Bolt / Screw Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Size | 1/8 to 1”, ½ Inch to 60 Inches, Custom Sizes available on request |

| Working Pressure | Up to 6000 PSIG, valves are also available that can handle higher pressure |

| End Connection | Male and Female NPT, BSPT, Socket Weld (SW) or Dual Ferrule Tube Connections, Male to Female, Female to Female |

| Temperature Rating | PTFE 450F,(232C)/Grafoil 700 F(371C) |

| Pressure Rating | 150#,300#,600#,800#,1500# |

Ball Valves

Gate Valves

Globe Valves

High Pressure Valves

Steam Trap Valves

Plug Valves

Butterfly Valves

Needle Valves

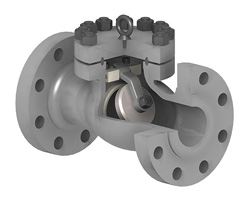

Check Valves

Manifold Valves

Jacketed Valves

Diaphragm Valve

| Valve Type | D & M Standard | Connection End | Operator |

|---|---|---|---|

| Gate Valve | API 600,API 6D,API 603,API 602,API 6A,ASME B16.34,DIN1984,JIS2071 | Flange, BW, SW, Thread | Handwheel, Worm Gear, Pneumatic Actuator, Electric Actuator |

| Ball Valve | API 6D,API 608,BS5351,ASME B16.34,DIN1983,JIS B2071 | Flange, BW, SW, Thread | Lever, Worm Gear, Pneumatic Actuator, Electric Actuator |

| Check Valve | API 6D,API 594,BS 1868,ASME B16.34,DIN13709,JIS B2071 | Flange, Wafer, Thread | – |

| Globe Valve | BS 1873,ASME B16.34,EN 588,DIN 3202,JIS 5752 | Flange, BW, SW, Thread | Handwheel, Worm Gear, Pneumatic Actuator, Electric Actuator |

| Butterfly Valve | API 609,MSS SP-68,DIN593,JIS B2071 | Flange, Lug, Wafer | Handle, Worm Gear, Pneumatic Actuator, Electric Actuator |

For water delivery systems, a gate valve is the most typical type of valve. It functions as a linear-motion isolation valve and can stop or start the flow. The closure element on a gate valve slides into the flow stream to provide shutoff, hence the term "gate valve." Gate valves can be divided into two main types: Parallel and wedge-shaped. The parallel gate valves use a flat gate between two parallel seats, and a popular type is the knife gate valve designed with a sharp edge on the bottom of the gate.

| Standard | BS 1414/ BS 5352/ API 600/ API 602 / API 6D / ASME B 16.34 / API 598 |

| Stainless Steel (BAR ST0CK) | RATING: 150#/300# SIZE: 8 MM TO 100 MM |

| Cast Carbon Steel/Stainless Steel/Alloy Steel | RATING: 150#/300#/600#/900# SIZE: 15 MM TO 600 MM |

| Forged Carbon Steel/Stainless Steel | RATING: 150#/300#/800#/1500# SIZE: 15 MM TO 50 MM |

| Cast Iron | RATING: 125#/150# SIZE: 25 MM TO 600 MM |

| Forged Range | Cast Range | |

| DESIQN (Mfg.) STD. | BS 5352 | BS 1868/API 6D |

| TEST (Inspection) STD. | BS 6755 | BS 6755/API 6D |

Globe valves, in contrast to gate valves, can be used to control flow or pressures as well as completely stop flow. It may occasionally be used as a check valve or a pressure relief valve. The globe valve has a significantly higher pressure loss in the fully open position when compared to a gate valve or ball valve. Typically, when installing globe valves, the inlet should be placed beneath the valve seat. The valve can be set up so that the flow enters over the seat's top and passes through it for severe throttling applications.

| Standard | BS 5352/ BS 6755 / BS 1873 / BS6755 /ASME B 16.34 / DIN3356 |

| Stainless Steel (BAR ST0CK) | RATING: 150#/300# SIZE: 8 MM TO 100 MM |

| Cast Carbon Steel/Stainless Steel/Alloy Steel | RATING: 125#/150# SIZE: 25 MM TO 600 MM |

| Forged Carbon Steel/Stainless Steel | RATING: 150#/300#/800#/1500# SIZE: 15 MM TO 50 MM |

| Cast Iron | RATING: 150#/300#/600#/900# SIZE: 15 MM TO 40 MM |

| Forged Range | Cast Range | |

| DESIQN (Mfg.) STD. | BS 5352 | BS 1873 /DIN 3356 |

| TEST (Inspection) STD. | BS 6755 | BS 6755 |

Ball valves regulate flow by sandwiching a metal ball with a hole through its centre between two seats. Ball valves are capable of throttling gases and vapours and are particularly helpful in low flow situations. They are used in many hydrocarbon process applications. Ball valves come in four different main categories: full port, normal port, reduced port, and v port.

| Body | Two Piece, No Welding |

| Size | 1/4", 3/8", 1/2", 3/4", 1" |

| Material | Different grades of materials like SS 304 / SS 316 / SS 316 L - Nace / Hastelloy C / Monel / Inconel offered on request |

| End Connections | NPT / BSPP / BSPT / METRIC |

| Stem | Rolled Stem Threads for Enhanced Cycle Life |

The purpose of a non-return valve, often referred to as a check valve, clack valve, one-way valve, or retention valve, is to only permit fluid movement in one direction, preventing the liquid or gas from flowing back upstream of the valve. Non-return valves, which can be placed anywhere in a circuit, are a crucial part of air systems. Their purpose is to open to let air flow in and prevent air from seeping back upstream. Non-return valves are compact and frequently have a simple design, making them lightweight parts.

| Standard | BS 6755/ BS 1868/ ASME B 16.34 / API 6D |

| Stainless Steel (BAR ST0CK) | RATING: 150#/300# SIZE: 8 MM TO 100 MM |

| Cast Carbon Steel/Stainless Steel/Alloy Steel | RATING: 150#/300#/600#/900# SIZE: 15 MM TO 600 MM |

| Forged Carbon Steel/Stainless Steel | RATING: 150#/300#/800#/1500# SIZE: 15 MM TO 50 MM |

| Cast Iron | RATING: 125#/150# SIZE: 25 MM TO 600 MM |

| Forged Range | Cast Range | |

| DESIQN (Mfg.) STD. | BS 5352 | BS 1868/API 6D |

| TEST (Inspection) STD. | BS 6755 | BS 6755/API 6D |

| Operator | Size Range |

|---|---|

| Handwheel | 2” – 10” – Class 150, 3002” – 6” – Class 600 |

| Gear Operator | 12” & Above – Class 150 & 3008” & Above – Class 60012” & Above – Class 900 & 1500 |

Max Steel & Engineering Co. manufactures and exports Valves to various countries such as Saudi Arabia, Bangladesh, United States, United Arab Emirates, Canada, Angola, Argentina, Austria, Azerbaijan, Pakistan, Peru, Chile, Kuwait, Mexico, Malaysia, Nigeria, Serbia, Singapore, Taiwan, Chile, Venezuela, Ecuador, Netherlands, Brazil, Vietnam, South Africa, Nigeria, Mexico, Turkey, Hungary, Algeria, Belarus, Belgium, Bhutan, Bolivia, Bulgaria, Croatia, Czech Republic, Estonia, Finland, Greece, Italy, Japan, Libya, Colombia, Ghana, Iran, Denmark, Poland, Australia, Afghanistan, Bahrain, Costa Rica, Egypt, Iraq, Jordan, South Korea, Kazakhstan, Sri Lanka, Lithuania, Norway, Oman, Philippines, Poland, Qatar, Spain, France, United Kingdom, Indonesia, Israel, Iran, Russia, Romania, Thailand, Trinidad & Tobago,Tunisia, Ukraine, Yemen, Hong Kong, Gabon, China, Portugal, Switzerland, New Zealand, Sweden, Slovakia, Kenya, Lebanon, Morocco, Mongolia

Max Steel & Engineering Co. manufactures and exports Valves to multiple cities such as Mumbai, Thane, Navi Mumbai, Pune, Pimpri-Chinchwad, Vadodara, Kolkata, Gurgaon, Ahmedabad, Seoul, Hyderabad, Singapore, Abu Dhabi, Tehran, Calgary, Noida, Riyadh, London, Coimbatore, Jakarta, Istanbul, Bangkok, Kuwait City, Sharjah, Muscat, Edmonton, Busan, Mexico City, Doha, New Delhi, Bengaluru, Chennai, Surat, Bhopal, Ulsan, Faridabad, Houston, Dubai, Jeddah, Aberdeen, Cairo, Geoje-si, Perth, Santiago, Chandigarh, Indore, Kuala Lumpur, Rio de Janeiro, Dammam, Melbourne, Madrid, La Victoria, Bogota, Lahore, Los Angeles, Algiers, Chiyoda, Ankara, Ho Chi Minh City, Toronto, Hong Kong, Howrah, Sydney, Ahvaz, Karachi, Rajkot, Brisbane, Petaling Jaya, Ernakulam, Secunderabad, Gimhae-si, Al Jubail, Port-of-Spain, Thiruvananthapuram, Milan, Atyrau, Lagos, Hanoi, New York, Caracas, Vung Tau, Al Khobar, Manama, Montreal, Granada, Courbevoie, Visakhapatnam, Ludhiana, Moscow, Dallas, Haryana, Colombo.

Our Mission

Our mission is to be a premier provider of stainless steel solutions, offering products that meet the highest industry standards and exceed the expectations of our customers. We strive to contribute to the success of our clients by providing them with durable, innovative, and sustainable stainless steel products.

Max Steel & Engineering Co. provides Valves at reasonable prices in the market. You can Contact us to get the updated price list of Valves.